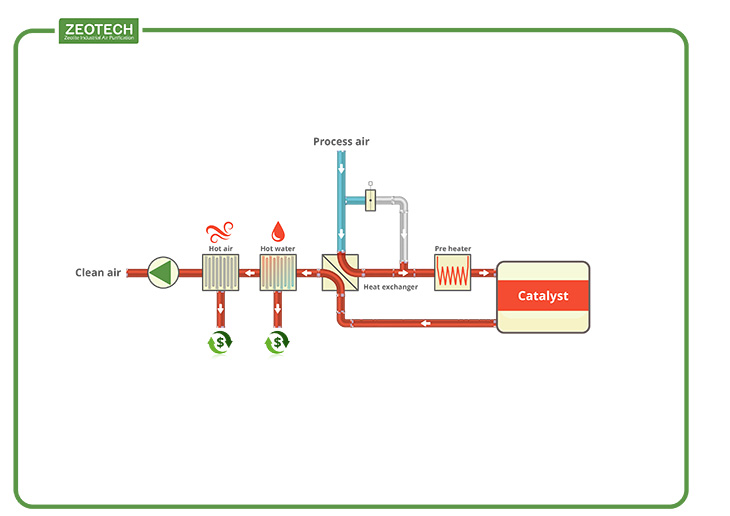

CATALYTIC RECUPERATIVE INCINERATION

Direct Incineration – when concentration isn’t necessary

Our direct incineration system is used to purify industrial air when the levels of VOCs in the process air are very high (more than 6-7g/m3), and there is no longer any need to up-concentrate.

High purification rate with direct incineration

Catalytic recuperative incineration gives a purification rate of almost 100 %.

Short start-up time

When using catalytic recuperative incineration, it never takes more than 30 minutes to make the purification system operational.

Heat recycling lowers operating costs

High temperatures following incineration makes it easy to use the surplus heat directly in the production process and to heat the facilities.

This lowers the total operating costs.

Are you emitting ozone?

Some productions do. We also offer a ozone catalyst to eliminate ozone from process air.